Producing musical instruments is a delicate craft, but technology enables companies to manufacture precision parts quicker than ever. Whether it’s brass instruments or custom guitars, automation is ringing changes across the industry.

Brands like Gibson and Fender now rely on precise 3D modeling and CNC routing to create the necks and bodies of vintage guitar models. Some musical instrument component manufacturers are automating parts of their production processes for increased output, improved quality, and decreased costs. However, these delicate musical products and assemblies are often transferred, stored, and manipulated manually to prevent damage.

Brands like Gibson and Fender now rely on precise 3D modeling and CNC routing to create the necks and bodies of vintage guitar models. Some musical instrument component manufacturers are automating parts of their production processes for increased output, improved quality, and decreased costs. However, these delicate musical products and assemblies are often transferred, stored, and manipulated manually to prevent damage.

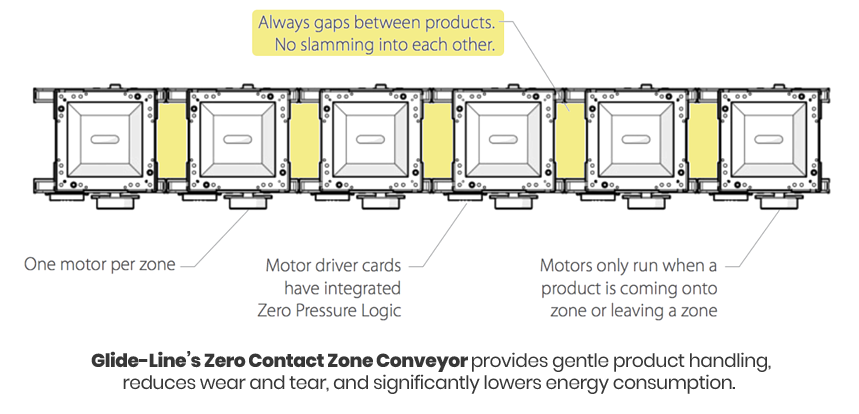

With a delicate solution like Glide-Line’s Zero Contact Zoned Conveyor, you can fixture musical instruments to ensure no collisions, prevent jostling, and automate the flow of products between production processes. Here’s how you can convey delicate musical instruments for improved manufacturing and assembly at your facility.

Convey and Transfer Musical Instruments Gently at Your Manufacturing Facility

Most production techniques for musical instruments remain labor-intensive. Experienced workers will wire amps by hand or assemble guitars with binding and pressing operations that take years to master.

Whether it’s selecting the right body and neck combination from the mill house and transferring it to the production floor, or moving the electronic parts of a keyboard to an assembly line for installation, all workpieces require gentle handling to prevent damage.

Whether it’s selecting the right body and neck combination from the mill house and transferring it to the production floor, or moving the electronic parts of a keyboard to an assembly line for installation, all workpieces require gentle handling to prevent damage.

For many manufacturers, the risk of damage is why they still prefer to move products and parts manually during manufacturing processes.

With Glide-Line’s conveyor and transfer systems, this is no longer necessary. You can develop a conveying and transfer solution that guarantees zero damage, improves overall equipment effectiveness, and provides precise control during every stage of the manufacturing and assembly process.

Handling Delicate Musical Instruments with a Zero Contact Zoned Conveyor

To prevent product-to-product contact, a Zero Contact Zoned Conveyor controls every section of the conveyor individually. Each workpiece moves independently and can’t enter a zone until the upstream section is clear.

This design allows you to configure a system that gently handles each workpiece either directly on the line or fixtured on a pallet. The 24v DC drives provide gentle stops and starts, preventing jostling within the different zones. Additionally, you can handle wider products by increasing the number of strands of the conveyor.

A Zero Contact Zoned Conveyor provides unmatched product handling capabilities, including:

- The smooth and gentle movement of workpieces between process stages with zero product-to-product collisions

- A highly configurable platform that solves almost any application where product damage remains a concern

- An ergonomic solution to move, transfer, and present workpieces to robots or operators for delicate subassembly tasks

Because of the modular design, you can integrate the conveyor with your existing equipment and machines. Accessories and custom standard solutions deliver additional product manipulation capabilities to locate, rotate, or transfer workpieces automatically between conveyors and workstations.

Automate the Product Handling and Manipulation of Delicate Musical Instruments and Parts

Controlling products and components between processing stages requires integrated devices that can merge, shuttle, divert, and manipulate items efficiently. Glide-Line’s conveyors interface with accessories like vertical transfer units, lift and locate devices, or drop and rotate transfers (DART, shown below) to ensure expert control during the entire assembly process.

Bypass stations allow products to keep flowing as operators complete their assembly tasks. Tilt decks provide workers with ergonomic access to workpieces while custom lift and rotate devices make it easy to manipulate products on the conveyor.

To solve unique application challenges, Glide-Line’s accessories can:

- Automate the movement and transfer of workpieces between all processing stages without risking damage to delicate instruments

- Deliver or retrieve workpieces to and from storage areas with automated locating, stacking, and sorting operations

- Present workpieces to operators or robots safely without risking damage to the product or injury to the workers

Glide-Line’s conveyors and accessories are easy to integrate, allow for nearly infinite configurations, and help to reduce operator fatigue that could lead to human error. What’s more, you can start designing your solution with our in-context configuration tool called IMPACT! right now.

Create the Perfect Rhythm for Your Musical Instrument Manufacturing Processes with Conveyor Solutions from Glide-Line

To assist application engineers, Glide-Line develops innovative solutions that can accommodate unique manufacturing challenges. Our systems deliver precise control during every stage of the production and assembly process. With the shortest lead time in the industry and a proven design that will increase your production efficiencies, you can trust Glide-Line with all your musical instrument conveying needs.

To start automating your musical instrument handling with advanced conveyor and transfer systems from Glide-Line, contact us today.

Leave a Comment