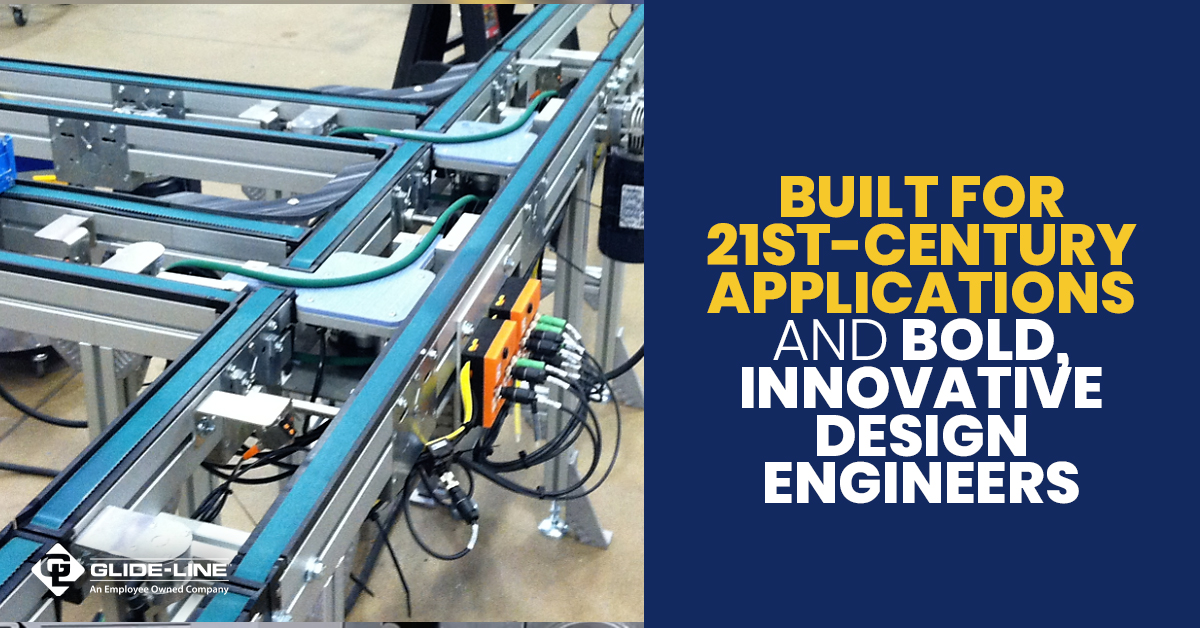

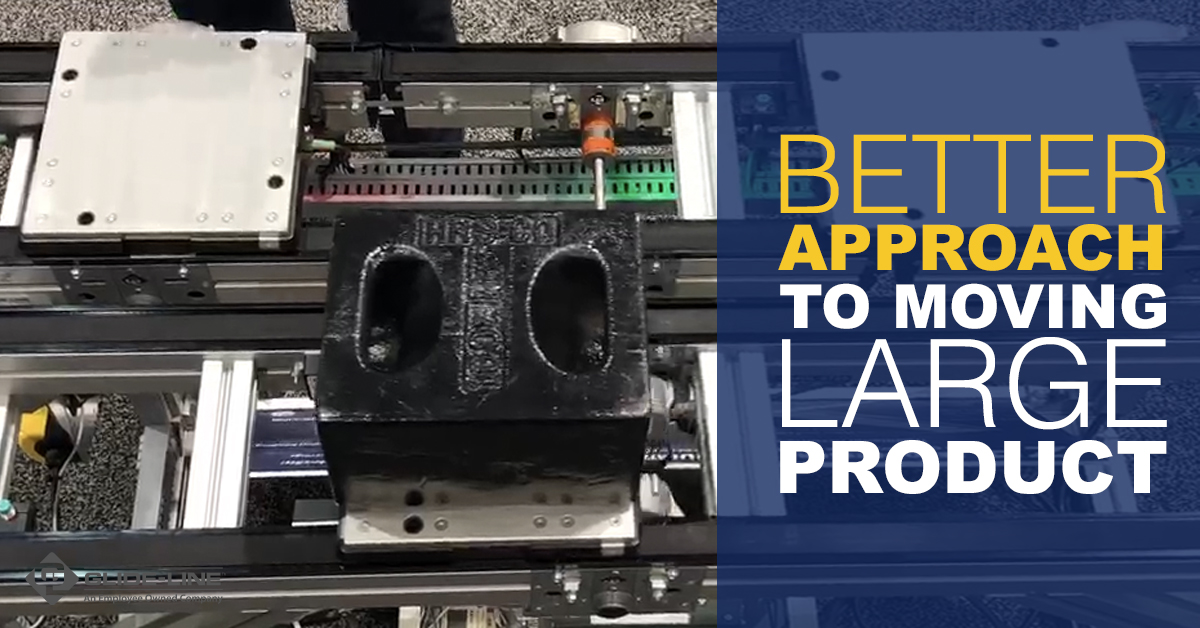

As manufacturing practices continue to rapidly change, it can be hard for your clients to know when to take on an investment like an AMR. While the costs may be high, not installing the motorized robots could be short-sighted. The good news is that there are options to optimize your clients’ AMRs’ efficiency, generating a higher ROI while improving work conditions and automating additional processes with the AMRs. An innovative, flexible conveyor solution, built for the top of the AMR, from Glide-Line is one of those options.

Read More