Do you run a facility that sends products down an assembly operation without a pallet?

Conventional product accumulation handling methods can typically do the trick for products you place on pallets. The pallets keep objects in place while moving down the assembly line. But unique, palletless products require unique solutions.

To keep palletless products from jostling against each other during the accumulation process, you’ll want to learn more about a Zero Contact Zoned Conveyor.

How to Improve the Accumulation Process of Palletless Operations

A palletless container being conveyed offers very little control of the product – a big problem if your products are fragile. Zero Contact Zoned Conveying systems deliver a unique solution to conveying a product without a pallet.

Control Each Zone

The Zero Contact Zoned Conveyor gives you precise control over each assembly’s accumulation. With a simplified control scheme, products accumulate without ever touching, and you can configure the system according to your exact acceleration, deceleration, and speed requirements. This solution offers controlled zones that run individually by DC motors or AC motors. With individual sections of conveyors, you’re in control!

The Zero Contact Zoned Conveyor gives you precise control over each assembly’s accumulation. With a simplified control scheme, products accumulate without ever touching, and you can configure the system according to your exact acceleration, deceleration, and speed requirements. This solution offers controlled zones that run individually by DC motors or AC motors. With individual sections of conveyors, you’re in control!

Reduce Wear and Tear

Having products travel from one conveyor to another down a line without bumping into another object reduces wear and tear on the belts. Furthermore, the conveyor does not have friction working against it as products accumulate - saving on energy costs.

Applying Zero Contact Zoned Conveying to Roller Chains vs. Timing Belt Systems

Whether you run roller chain conveyors or timing belt systems, you can implement a zoned conveying solution to your operation. The most significant difference between zoned conveying for roller chains and the timing belt is the actual weight of the product being conveyed. Heavier objects or applications would require roller chain conveyors.

Regardless, there are many benefits of using contactless zoned conveying solutions for totes and products differently on the line including:

- Less handling of the product by people on the line

- No need to return empty pallets or invest in pallets themselves

- Gentle stops and smooth starts for product assembly operations

- Accumulate products without compromising on space, control, or efficiency

Accumulate a Palletless Operation Without Damaging Fragile or Sterile Products

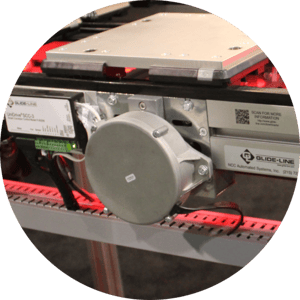

When you're assembling unique, irregularly-shaped, or large products directly on a conveyor, your accumulation process can damage parts. Glide-Line's gentle control zone by zone conveyor design addresses this challenge.

The Zero Contact Zoned Conveyor solution can provide a better way to accumulate products without pallets. Since products do not travel down a single-belt system, you have more control over stops and starts, keeping products free from damage.

Keep palletless assembly processes from damaging your products. Contact us to see how Glide-Line can help.

Leave a Comment