Vertical transport units, or VTUs, are often the first consideration when you’re building a pallet conveyor automation system with space constraints. While other belt conveyor manufacturers may be able to provide traditional (some may say boring!) VTUs for your automation system, our team urges applications engineers to think outside the norm when it comes to applying VTUs in their modular conveyor systems, starting with asking these five simple questions.

Innovative Solutions Using the VTU

VTUs are typically offered to handle lightweight, medium, and heavy-duty loads. You’re also able to configure the VTU to be open-ended on the top side, so the manufacturing process can continue to perform at any height your process requires. Some of our clients’ most innovative solutions have come from using a vertical transport unit to save space in their application engineering.

One example is a pass through design for the VTU – a lift within a lift. I’ve included an illustration below. This particular design saved one customer thousands of dollars, since they could accomplish the same goal and avoid more expensive bypass conveyors around pallet elevators.

pass through design for the VTU – a lift within a lift

pass through design for the VTU – a lift within a lift

Typically, when a pallet goes into a VTU lift, it would lift up and unload. But the product that was coming along the bottom had to wait for the pallet to come back down. Instead of bypassing the elevator with the waiting product, we built the “lift in a lift” VTU.

This solution has four upright vertical corners, and the two conveyors traveling up or down within the lift. The top conveyor would lift a pallet up to be unloaded, and the conveyor underneath would simultaneously lift up to the position of the top one to allow the continuous flow of production. No stopping to wait for the top conveyor to drop back down into place.

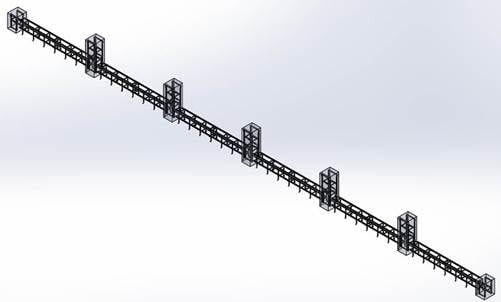

This additional picture shows the five pallet elevators on this conveyor working together to accomplish the customer’s goal.

Example of 5 pallet elevators on a conveyor to avoid bypassing.

Example of 5 pallet elevators on a conveyor to avoid bypassing.

5 Questions to Ask Before Selecting a VTU Manufacturer

![]() Are your VTUs configurable?

Are your VTUs configurable?

This is the most important question if your customer’s manufacturing process requires a unique solution. You can add configurable VTUs to your specific engineering design requirements in multiple ways for multiple functions, but some conveyor manufacturers cannot accommodate these use cases.

For example, an over/under conveyor system utilizes a VTU as a pallet elevator to return the empty pallets under the trunk line back to the line start. This can save a lot of square footage, since the “race track” loop in a standard conveyor can sometimes get fairly wide.

Whether your customer is looking for space savings or simply efficiency in their overall process, vertically transporting products can be the perfect solution – but the innovation doesn’t stop with thinking up instead of out. Read more in our blog post Unique Assembly Conveyor Layouts and The Best Applications.

![]() What is the availability of your VTUs?

What is the availability of your VTUs?

Crunched for time? When your customer needs a specialized solution, there’s typically a trade off between speed and customization. Usually, time is forfeited in favor of customization, or you need to compromise your ideal design in favor of what’s quick and standard. However, that’s not the case for a manufacturer like Glide-Line. Many of the typically customized elements of a VTU come standard. So, you’re not compromising your design, and manufacturing and delivery speed stay intact.

![]() What’s the cost?

What’s the cost?

Cost is an obvious question when it comes to planning your automated conveyor system. This number should account for the standard VTUs you may need and also for any customizations you’ll require. Ideally, you’ll be able to engineer the system designs yourself online and receive instant quotes using a configurator like IMPACT!.

![]() What’s the expected delivery time?

What’s the expected delivery time?

Delivery time can be impacted by the number of parts and the pieces you select, including any customizations you may need. But if you choose the right conveyor manufacturer, delivery times can be significantly shorter. For example, Glide-Line’s conveyors are simpler, require fewer parts to build, and our process to manufacture is shorter. This dramatically reduces the delivery time needed for your client’s conveyors.

![]() What does typical maintenance look like for your VTUs?

What does typical maintenance look like for your VTUs?

Simpler conveyors with fewer parts to break down and easier access to those parts will be a welcome innovation by your customer. Ask the conveyor manufacturer about access, time, and cost of replacement parts before making your decision.

Customizations are Standard

The vertical transport unit offered by Glide-Line is the best fit for many of our clients because of its endless options in pallet sizes. You’re able to configure it to any customized size,without the customized pricing. Using IMPACT!, our unique configurator, any size tray or pallet your customer requires is already a cost-effective option. This saves time on delivery and saves your client money because it’s built to their exact specifications, right out of the gate, with no additional customization needed.

For more information, check out our ebook, Ultimate Guide To Creating A Flexible Automation Conveyor Application Solution.

Leave a Comment