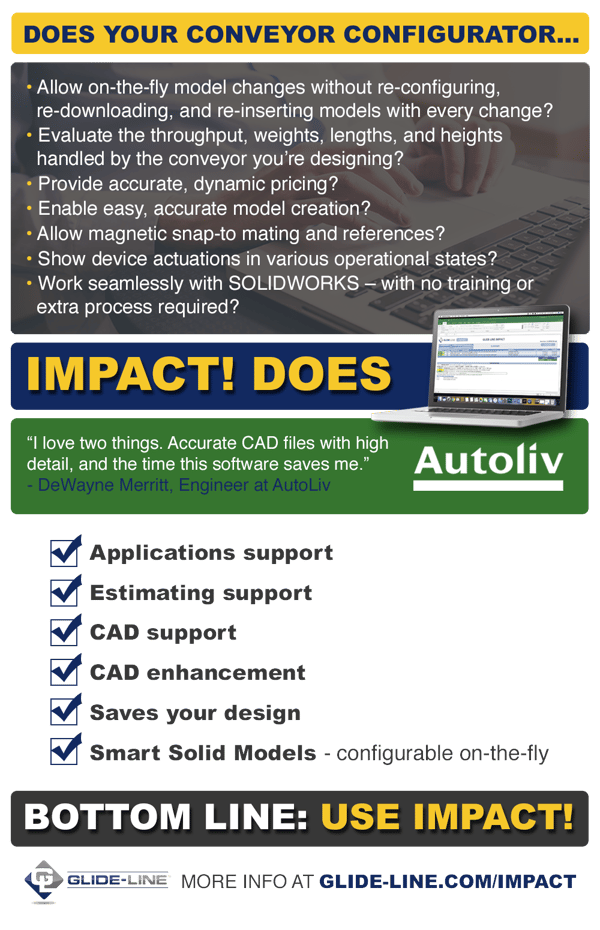

IMPACT! is the most advanced, yet simplest, automation conveyor design software available.

It combines the five elements every conveyor system design integration needs:

- CAD blocks

- Snap-to (magnetic) pairing/mating in SOLIDWORKS

- Firm, pricing

- Application calculations

- Part number generation

This is not your typical conveyor configurator. It’s designed to make automation conveyor pricing go quickly and smoothly. It’s all done using Excel, so if you can use Excel, you can use IMPACT! – no additional training required. If you happen to be a SOLIDWORKS user, you will get the benefit of precise solid automatic model creation with precise 3D solid conveyor models in SOLIDWORKS, while simultaneously providing accurate pricing in a fraction of the time you would spend using other configurators.

Here’s how it works.

Instead of using a website to enter information and configure the product, then downloading a CAD model and receiving pricing via email, IMPACT! is conveyor software that lives on your computer and pairs with SOLIDWORKS. There’s nothing to download once you’ve started using the configurator.

You’re able to play, create, and build in it, because any changes you make are instantly made in your SOLIDWORKS master assembly. And, those changes automatically update in your Excel-based pricing table with accurate part numbers and pricing. You can see the effects without taking extra steps to download, then upload, then manually re-insert and re-mate parts. There’s no need to stop your creative process for the “busy work;” it’s all done for you.

“I love two things. Accurate CAD files with high detail, and the time this software saves me.” - DeWayne Merritt, Engineer at AutoLiv

In essence, IMPACT!:

- Evaluates the throughput, weights, lengths, and heights handled by the conveyor you’re designing

- Provides accurate, dynamic pricing

- Enables easy, accurate model creation

- Allows magnetic snap-to mating

- Shows device actuations (various operational states)

- Works seamlessly with SOLIDWORKS – no training or extra process required

And, our team provides application support and guidance along the way if you need some additional brainpower. Here's a handy checklist to keep in mind if you're comparing other configurators. Keep reading below for more details.

Conveyor Output on the Fly

IMPACT! helps applications engineers to choose the right equipment based on their customers’ goals. You’ll enter the product information (weight, size, number, speed needed) and those variables are used to ensure the conveyor is sized correctly for the application, and the materials and components make it run as needed, too.

Accurate, Dynamic Pricing

Pricing isn’t an estimate when you’re using our unique conveyor configurator. You don’t even need to speak with someone from our team before using the quote given using IMPACT!. As you change, update, and develop your conveyor design, you can see the pricing transition as well. Dynamic pricing for a dynamic design eliminates the guesswork in your process.

Easy, Accurate Model Creation

As an integrator, estimates and budgets are incredibly important upfront, and accuracy is even more important once the project is underway.

Using IMPACT!, you can create actual solid models – these aren’t just approximately accurate, they’re dead-on accurate. It’s easy to see how things fit together and envision how they’ll work in your customer’s automation process from any angle with 100% accurate models.

And the parts you select are automatically updated for you to order when your design is finalized; they change automatically as your design develops, so there’s no need to check accuracy in multiple places.

Snap-to Mating

Eliminate the time-consuming step of mating CAD blocks in SOLIDWORKS by using IMPACT!. The software utilizes magnetic snap-to mating, so getting your blocks into the model accurately is as quick and easy as possible.

Multiple Device Actuations

View your design from all of its motion states to ensure there aren’t obstructions and it meets your design goals using IMPACT! for configuration. Whether you’re determining where to mount a robotic arm or where to place a support post within your master layout, IMPACT! can assist.

IMPACT! Simply Works with SOLIDWORKS

Using Glide-Line’s advanced, proprietary API bridge, IMPACT! gives applications engineers and design engineers access to create, build, and adjust 3D or solid models that pair easily with SOLIDWORKS. This conveyor configurator is so unique that SOLIDWORKS featured IMPACT! in a case study.

IMPACT! is Excel-based. You define a model, update and change it without starting over as you progress, and then send it to SOLIDWORKS with the click of a button. This offers you flexibility and simplicity in your everyday work.

IMPACT! also helps applications engineers and design engineers work more cohesively. There’s no need to re-create a design from scratch once the project begins; it’s ready to go from concept to precision design to ordering as your internal integration process happens. Adding IMPACT! to your process eliminates:

- extra work,

- time spent waiting for pricing or change estimates, and

- inconsistencies between models and designs when changes are made

We created IMPACT! to make your job easier. If you know how to use Excel, you know how to use this program. There is nothing to learn. It will make you faster and more accurate, and you’ll have better models for your designs.

Don’t Call Us.

Okay, you can if you want – we do love to hear from you. But you don’t need to talk to anyone here for engineering, pricing, or part numbers; that’s part of the beauty of IMPACT!. Don’t take my word for it, though. As DeWayne Merritt, an engineer at AutoLiv, puts it: “I love two things. Accurate CAD files with high detail, and the time this software saves me.”

.gif?width=426&name=IMPACT-Incentive-first-time-user-v3%20(1).gif)

Leave a Comment