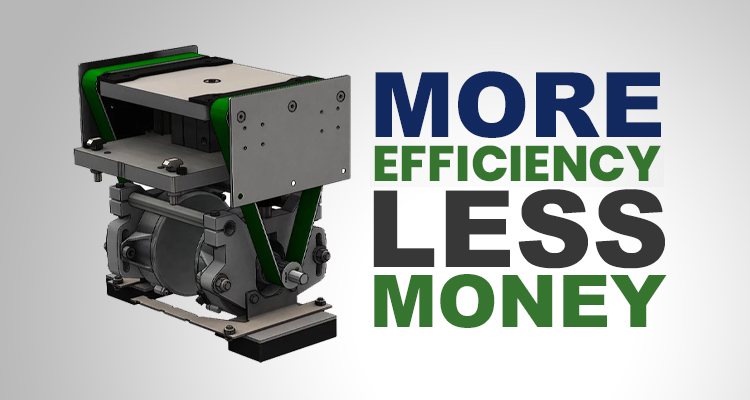

Online, buffering gets a bad rap. But when it comes to buffering in an automation process, there’s a simple but incredibly effective solution that saves space, saves money, and saves lead time. I won’t leave you hanging; read on to learn more about the Machine Buffering Solution from Glide-Line. Glide-Line’s Machine Buffering Solution is a vertical buffer. By stacking accumulated products vertically in a vertical sortation and storage device, this device is able to take the place of other accumulation or buffer solutions without taking up floor space. It can also be applied in an automation system as a racking or short-term storage solution. This simple solution is a standard option from Glide-Line, and it can be easily customized to fit your client’s automation process.

Read More